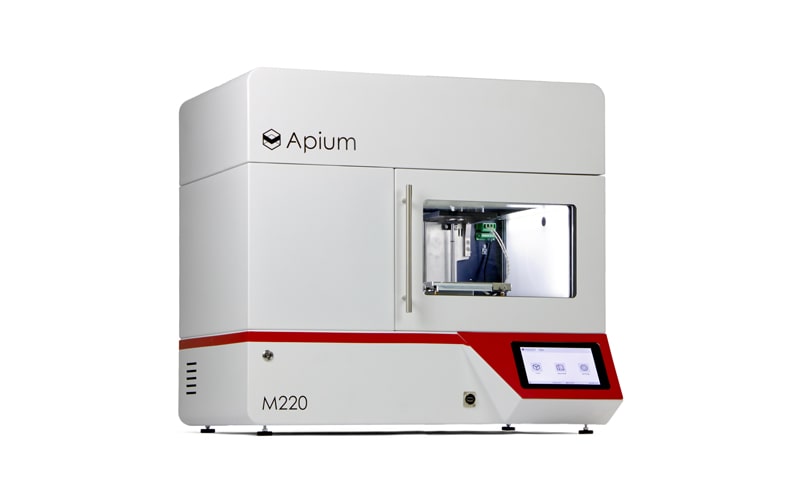

The Apium M220 is the world’s first 3D printer specifically designed for the manufacture of medical products and implants made from PEEK. All printer components in direct contact with the material being processed are made of certified, sterilisable medical-grade materials.

On the Apium M220 printer, an integrated filter system traps organic and inorganic contaminants from the room air. In addition, the hot air stream prevents particles or bacteria from settling on the printed part during the process. The extruder has been developed for flexibility and durability. All components in contact with the print material are made of medically compatible materials: PEEK, Titanium, 316L stainless steel and PTFE. In collaboration with Evonik, materials and filaments were tested for biocompatibility. The Vestakeep® i4 G resin from Evonik used in the printer meets ISO 10993-1 recommendations for permanent contact with tissue/bone and complies with ASTM F2026 – Standard Specification for Polyetheretherketone (PEEK) Polymers for Surgical Implants – allowing the production of Class III medical devices.

The Apium M220 has an integrated temperature sensor system. Once printing is complete, the user has access to the process protocol, from which the strength properties of the manufactured product can be assessed based on the sensor readings, and standardized calibration procedures guarantee consistent quality of the manufactured parts.

Technical specification

| Technology | FFF/FDM |

| Head temperature | up to 540°C |

| Hot air filtration system | up to 280°C |

| Layer height | 0,05 – 0,6 mm |

| Nozzle size | 0,2 – 0,8 mm |

| Working platform material | 316L stainless steel |

| Wall thickness | >250 µm |

| Working chamber | closed |

| Dimensions | 850x685x675 mm |

| Weight | 67 kg |

| Connectivity | WLAN, Ethernet |

| Noise emission | <70dB(A) |

| Data formats | .stl, .obj, G-code |

| Print material | VESTAKEEP® i4 G |