Knowledge has Layers™

Popularization of science and professionalization of knowledge are integral parts of Sygnis’ activities. In this segment, we present specialized articles on various branches of science and technology sectors.

We conduct webinars where we talk to prominent specialists from around the world. We share our know-how and offer comprehensive technology consulting.

[CASE STUDY] IDEA 3W statuettes for Bank Gospodarstwa Krajowego

The 3W: water-hydrogen-carbon project is a new initiative of the Bank of National Economy. The aim of the project is to support the world of

[CASE STUDY] Reclaim the bread! How did we make 3D printing filament with stale bread?

Together with REBREAD – an initiative aimed at solving the problem of bread waste in the world – we did a joint 3D printing project!

(Un)developed potential of 3D printing techniques in the implementation of circular economy

The modern economy is largely based on a linear economy model, where products are produced, consumed and dumped in landfills. This requires the constant exploitation

[CASE STUDY] Did you know that The Voice of Poland statuette is 3D printed?

We are already after the finale of the last edition of The Voice of Poland. On this occasion, we would like to remind you and

[CASE STUDY] Material testing on FlashForge Creator 4 machines in collaboration with Maxfilament

In cooperation with partners from Maxfilament, material tests have been carried out on our latest 3D printers from FlashForge – Creator 4 – to verify

Creator 4 industrial 3D printers from FlashForge in the Sygnis fleet

New machines from Flashforge Corporation have replenished the Sygnis machine park, increasing its production capacity, optimizing workflow and streamlining manufacturing processes. This is truly a

[CASE STUDY] 3D printing to help newborns

Neonatal surgery differs dramatically from adult surgery. Pediatric surgery requires greater delicacy, precision and faster response, all due to the still forming human body. Many

ZMorph joins the Sygnis Group

Soon we will be the largest Polish 3D printing company in terms of employees and revenue! As of July 29, 2022 (because that’s when we

Preparation of Smart-seq3xpress analysis in cooperation with the I.DOT device in order to learn about the transcriptome

High-throughput sequencing methods have allowed transcriptomics [1] to develop significantly over the past decade. The ability to in-depth study of complete transcriptomes using RNA sequencing

[CASE STUDY] CRN_01 “Hummingbird” – Original swabs design

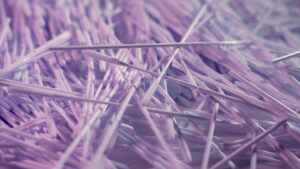

In 2020, in less than two months we created a project that redefines one of the most recognizable symbols of the pandemic – the swab.

Author’s design of a tourniquet on its way to the Eastern Front

The problem with the availability of tourniquets on the market prompted us to analyze the tourniquet manufacturing process from scratch and create a unique proposal.

The Digital Science and Technology Center (CNT) equipped with 3D metal printer from Aconity3D GmbH

We have completed the delivery of a specialized machine for metal 3D printing by Aconity3D GmbH. It was delivered to The Digital Science and Technology