New machines from Flashforge Corporation have replenished the Sygnis machine park, increasing its production capacity, optimizing workflow and streamlining manufacturing processes. This is truly a new quality of manufacturing in FDM technology.

The Sygnis machine park is located in Warsaw at 101 Żwirki i Wigury St. What used to be called the boiler room, the heat-providing heart of the University of Warsaw’s Department of Chemistry, today houses more than 70 machines working day and night in more than a dozen different manufacturing technologies. The most diverse projects – from the incredibly fascinating to the incredibly ordinary – are created right here in the Sygnis production center.

New quality of production

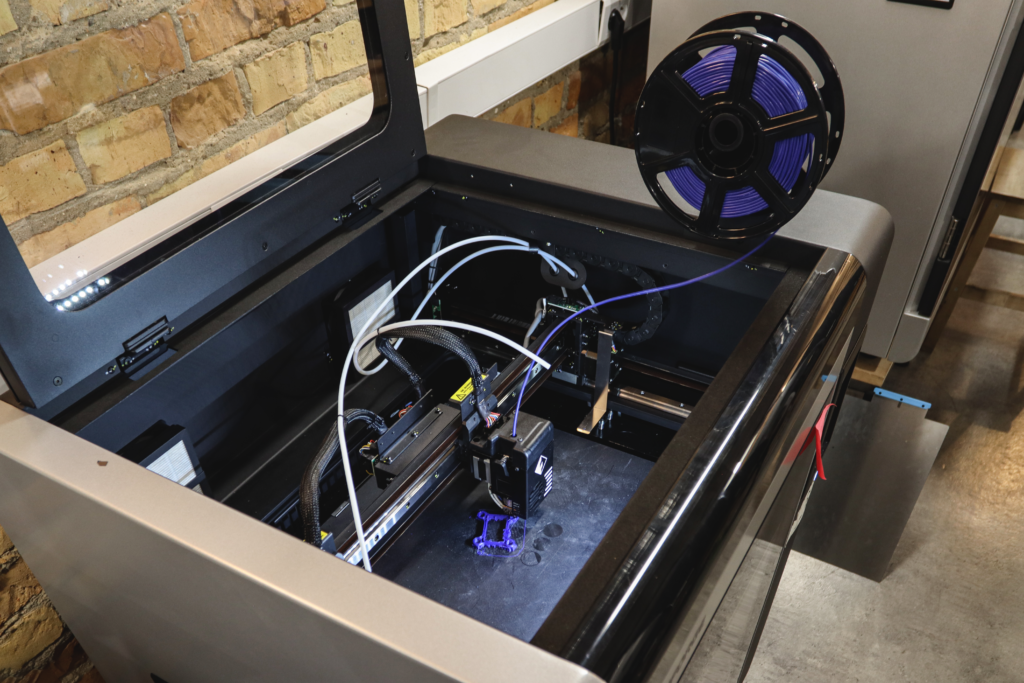

During the warm summer days of last month, our machine park was filled with brand-new Creator 4 machines from Flashforge. The giant 3D printer with a workspace of 400 x 350 x 500 mm is a real step, or even several steps, into the future for our production department.

“First of all, it is easier for us to manage manufacturing processes. Working with machines has become simpler. Both I, as production manager, and other employees save a lot of time by managing all production at once through FlashCloud,”, says Piotr Piskorski, production manager and engineer at Sygnis SA.

The ten Creator 4 3D printers in the Sygnis machine park are supported by software that makes production processes more consistent and automated. Our machine park is the first place in the world that has decided to base its production on a combined Creator 4 machine system.

“In our 3D printing lab, work has not only become more efficient, but also more impressive! Working 24/7, carrying out projects on demand, the machine park is the perfect place to showcase the production capabilities of 3D printing, which has already delighted our partners and customers” – declares Andrzej Burgs, CEO and Chairman of the Board Sygnis SA.

How does the Creator 4 3D printer production line automation work?

The newly developed FlashPrint 5 software can be integrated to control more Flashforge printers as it looks today in our fleet! The advanced software can preheat and maintain the temperature before and after printing. The thermal control system maintains a constant temperature inside the working chamber up to 65 ℃, reducing the thermal shrinkage of the model during the printing process. This ensures a successful 3D printing process, and once the process is complete, the system helps adjust the cooling temperature to prepare for the next print without having to wait again. This works perfectly when working with high shrinkage materials such as ABS or PP.

About the 3D printer

The 3D printer is equipped with two extruders with interchangeable modules and an advanced temperature control system. It has a library of parameters properly selected for many of the most popular consumables. The interchangeable modules and active temperature control inside the working chamber make 3D prints have excellent mechanical strength and high precision.

Great quality hardware

High-precision linear guides on the XY axes ensure printing accuracy, and the all-new S-type motion control will achieve smoother starts and stops, more accurate positioning and perfect accuracy of the printed model. The stainless steel body guarantees printer stability, reduces the risk of jitter and ensures balanced and efficient operation. An even larger working area will allow you to achieve multi-size prints.

A wide range of materials

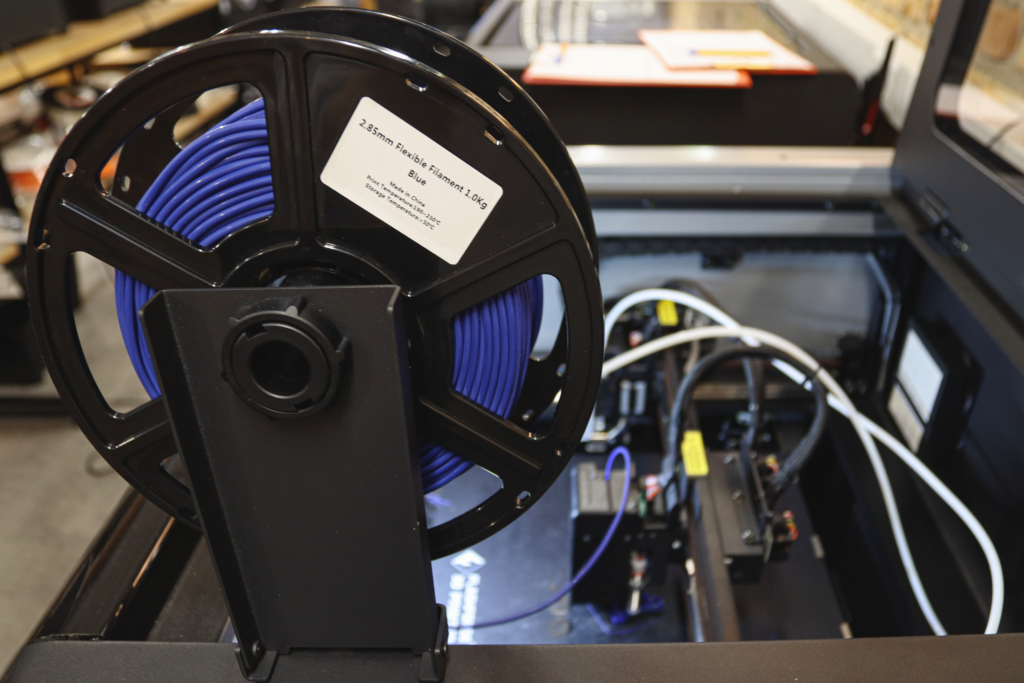

Creator 4 has built-in space for two types of spools (2kg and 1kg). The printer has been tested on materials such as PC / PA / PP / PETG / ASA / ABS / PLA / PC-ABS / PACF / PET-CF / PP-CF / PA- GF / PC-ABS / PP-GF / PPS- CF / TPU 85A / TPE / TPB / TPC. We are in the process of testing new 3D printing materials on Creator 4 printer in cooperation with MaxFilament. The effects are coming soon!

Factory of the future

The main advantage of the machine park is the ability to use a variety of 3D printing technologies and more. It includes 3D printers working in FDM/FFF, SLA, DLP, LCD, MJP, PolyJet, DIW, SLS technologies, among others, as well as an AD1 machine for the production of advertising signs, an Apium P220 machine printing in FDM technology with high-temperature, high-performance polymers (e.g. PEEK, CFR PEEK), Vacu3D thermoforming machine, laser/cutting plotter, 2D printing plotter, lathes/tapping machines and metalworking tools.