Together with REBREAD – an initiative aimed at solving the problem of bread waste in the world – we did a joint 3D printing project! Wait a minute – bread and 3D printing? How do you combine the two? It turns out that not only can it be done, but it can also be much needed. More details in the article below.

Where does stale bread come from in production?

For more than a year, REBREAD has been working to reduce discarded bread worldwide. It seeks out and explores ways to use stale bread as a raw material to create new, wholesome products. REBREAD reps knew about the possibilities of using bio-based polymers in 3D printing, corn starch or sugar beets, and saw the potential in crusted bread.

“Any way to save bread from becoming waste and keep it in the closed loop of production is the right way. We are looking for solutions that we could apply on a global scale. A friend of ours mentioned the high-tech company Sygnis, which might be open to such cooperation,” comments Bartlomiej Rak of REBREAD.

Andrzej Burgs, CEO of Sygnis SA, responded to the idea with great enthusiasm. He has an excellent understanding of the problem of food waste in the world and quickly declared his willingness to cooperate and try to use stale bread in the production of 3D printing material.

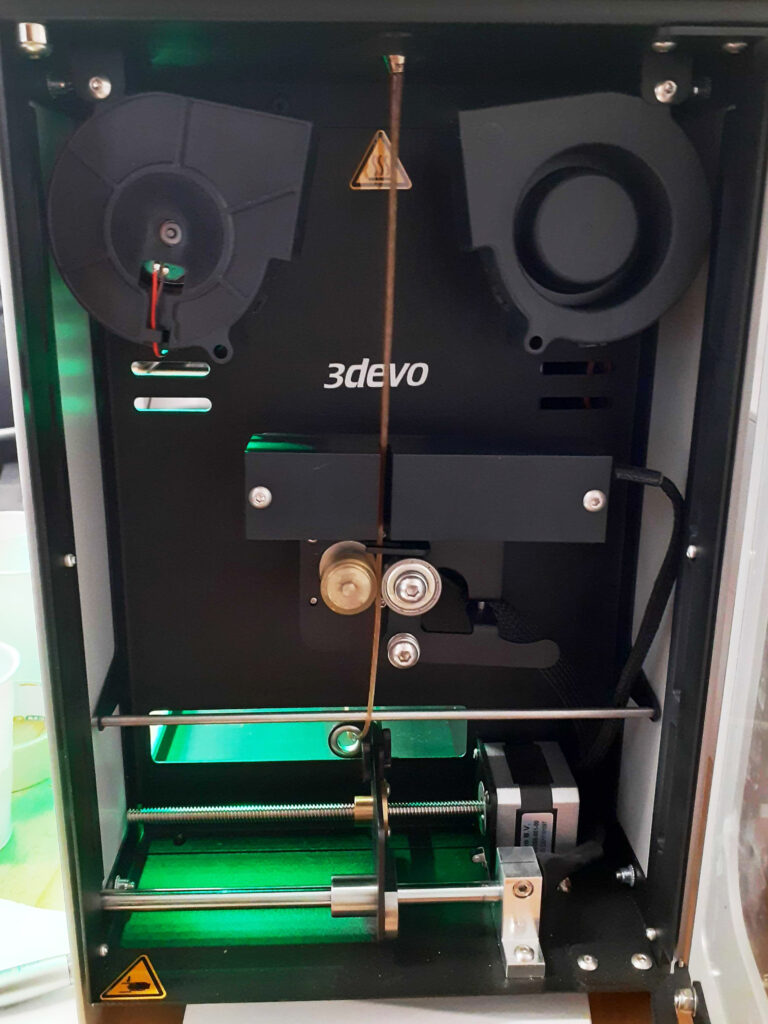

In April 2022, a bag of stale bread arrived in the Sygnis machinery park from REBREAD. What did we do with it? We took up the challenge, of course! We verified whether it was possible to create a filament based on biodegradable PLA (polylactide) material with the addition of dry bread. To do this, we used a set of 3devo machines, which are stationed in our machine park at Żwirki i Wigury 101. The project team consisted of two people: Joanna Wądołowska-Frej and Natalia Pawłowska, who at Sygnis are responsible, among other things, for carrying out research and development work directed at creating new types of 3D printing materials and recycling of filament.

The work on this project would not have been possible if it were not for the machines of Dutch company 3devo, which allow to carry out recycling processes and work on new types of materials for 3D printing.

3devo – trial-and-error machines… and ultimately successes

3devo is a technology company founded by young, inventive engineers in the Netherlands. Their mission is to create accessible and high-quality products to “close the loop” on the production, processing and reuse of 3D printing materials. They started their work in 2014, and today they provide complete solutions for working with new materials and recycling filament. Just such a set is in the Sygnis machine park.

You can read more about 3devo machines HERE.

3devo’s goal is to help companies, educational institutions and research labs transition to a more sustainable business model – not only from an economic perspective, but also from an environmentally friendly 3D printing practice. They remain focused on this goal by continuously improving their products and finding ways to take material innovation to the next level.

“We are working with 3devo because our visions of the future are aligned. We want to take care of the environment by promoting eco-friendly technologies that bring us closer to closing the waste cycle. We are committed to developing the potential of recycling 3D printing materials not only within our machine park, but also in industrial and research environments. Thanks to our Dutch partner’s solutions, research into new materials is easier to carry out, and the entire ecosystem of equipment takes up little space, offering endless possibilities in return,” says Joanna Wądołowska-Frej, an engineer at Sygnis SA’s R&D department.

What does the processing process look like?

We can easily grind the black bread because it is devoid of water. Then, we mix it with polymer granules at a ratio of 1:9 and can successfully extrude it with the 3devo Composer 450 machine.

But one step at a time…

After grinding the bread, we pour the pretreated mixture of granules and stale bread into the hopper, or hopper hopper. The mixture is fed into a screw/screw with a geometry that facilitates homogeneous mixing of the polymer with the additive. This means that both components are uniformly, equally mixed. To bring about complete melting of the polymer, the screw/worm guides the material through four heating zones, each of which has an independently set appropriate temperature. It can be neither too high nor too low. This allows us to change the state of aggregation of the material at the right rate without changing the chemical composition of the mixture.

The extruder at the end of the screw/screw has a nozzle with a diameter of 3mm, from which prefabricated filament flows steadily. Next to it is a sensor that tests the diameter of the filament. It indicates whether the resulting material has a constant diameter. In addition, thanks to feedback, the extruder is able to automatically adjust the tension force so as to maintain the diameter set by the user. What does this mean? It means no less than that the machine is able to maintain its own operating parameters to create filament for 3D printing again! That’s called full automation!

What did we manage to create?

Thanks to 3devo’s machines and the work of our R&D team, we were able to produce a 3D printing filament doped with stale bread, where about 90% of the material is PLA (polylactide) and 10% is dry bread. We conducted a number of tests that confirmed that we could successfully 3D print from our experimental filament.

The most difficult part was to prepare the right polymer mixture with black bread. The whole R&D process went quite smoothly, as 3devo provides ready-made material profiles for the most popular thermoplastics for 3D printing. They make it easy to work with new blends and experiment on your own,” comments Natalia Pawlowska, a junior engineer at Sygnis SA’s R&D department.

Experimental R&D projects are our daily bread

About 2 million tonnes of bread are wasted annually in Poland, indicating a sizable problem, and at the same time an opportunity for innovative solutions that could rescue unsold bread and create new products from it, exactly as in the case above.

“Our goal is to inspire others and encourage cooperation between different industries that will work together towards not wasting food and taking care of the closed loop in business. Our project with Sygnis brilliantly shows how waste in the food industry can become a raw material in a completely different sector,” explains Bartlomiej Rak of REBREAD.

More projects are ahead of us with the REBREAD initiative! We started off with a bump, but now with the confidence that we can produce functional 3D printing filament, who knows what ideas we’ll come up with next….