3D printing technology for power generation,

working with lead materials

Goal: To develop a versatile tool for prototyping and creating serial power frames.

A dedicated 3D printer that processes materials such as lead will allow the creation of frames and ultimately batteries with increased capabilities.

Obtaining the ability to create arbitrary 3D structures will translate into increased efficiency in the use of cells created by this method, as well as increase their electrical capacity.

The use of the machine as a prototyping tool for new power engineering solutions will reduce the prototyping of new solutions by 2-3 years, as well as make available previously unattainable possibilities (increasing lead-acid capacities).

Technology Readiness Level (TRL): 6

Working prototype - tested in the intended environment

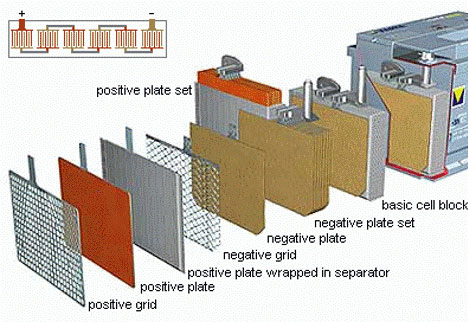

The machine uses additive manufacturing technology to print layers of specially designed lead meshes in shapes that are unattainable using conventional methods.

In addition, many production steps are automated and integrated into a single machine, saving time and money.

Innovative way of manufacturing lead-acid batteries