Research and development projects

The technology of printing from low-temperature glass using the proprietary LTG 3DP method allows the automation of many steps in the production of nanostructured fiber optic preforms. SYGLASS technology makes it possible to shorten the production process of one fiber optic cable by a minimum of fourteen times.

3D printing of glassy carbon directly from gas phase to the solid phase is a technology that represents a revolution in the way we have produced so far, such as EDM electrodes, bipolar plates for hydrogen fuel cells and biomaterials.

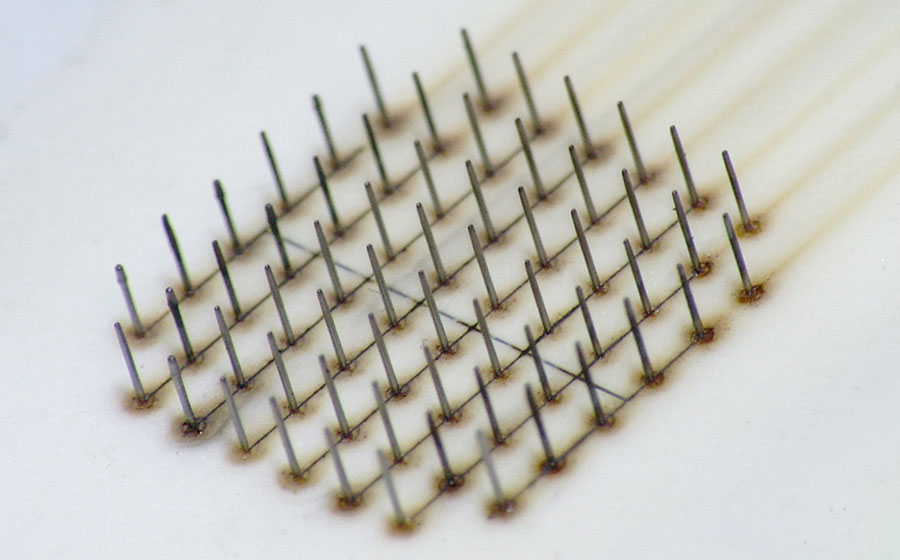

F-NIS will find its use in chemistry and materials laboratories, among research groups working on new materials, flexible robots, flexible electronics, ceramic insulators, UV-curable materials, silicones, conductive pastes and in research on new types of batteries.

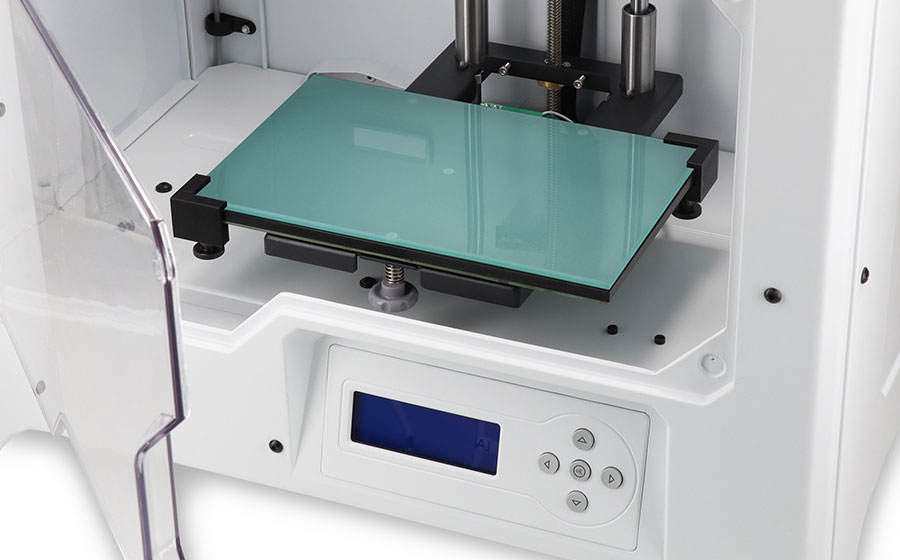

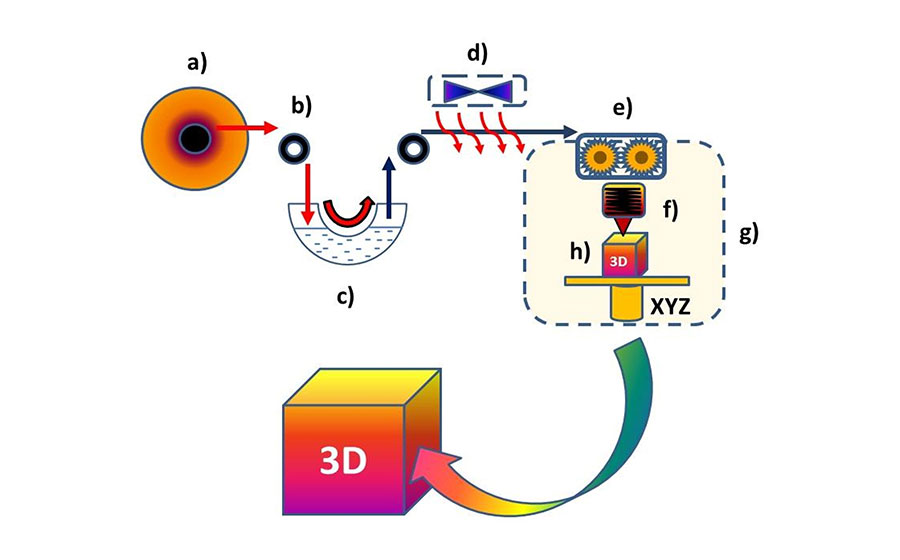

The project involves the construction of a multifunctional hybrid 3D printer with a real-time quality control system.

The goal of the project is to build a 3D bioprinter that, together with the developed bioinks, will allow the production of 3D prints for reconstructive treatment of urethral defects in children and adults.

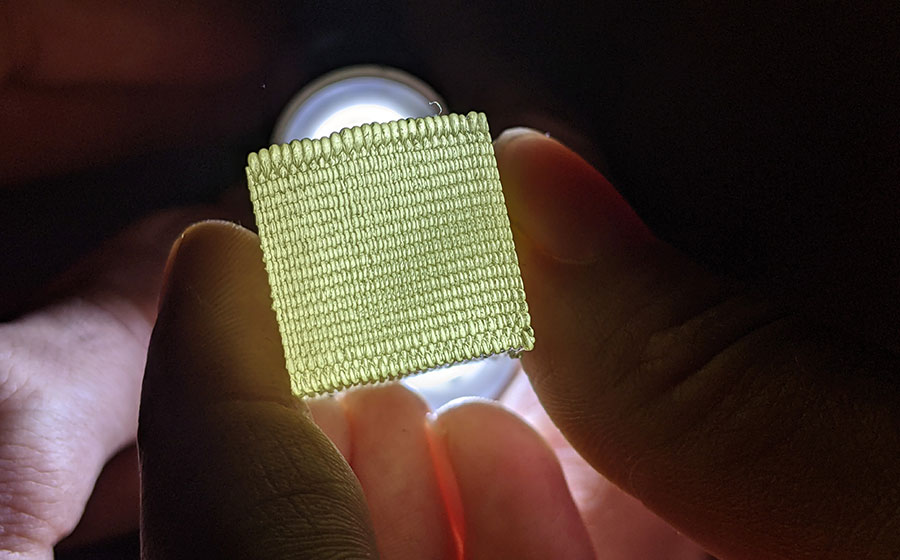

LFDM – Liquid for Fused Deposition Modeling

Coming soon

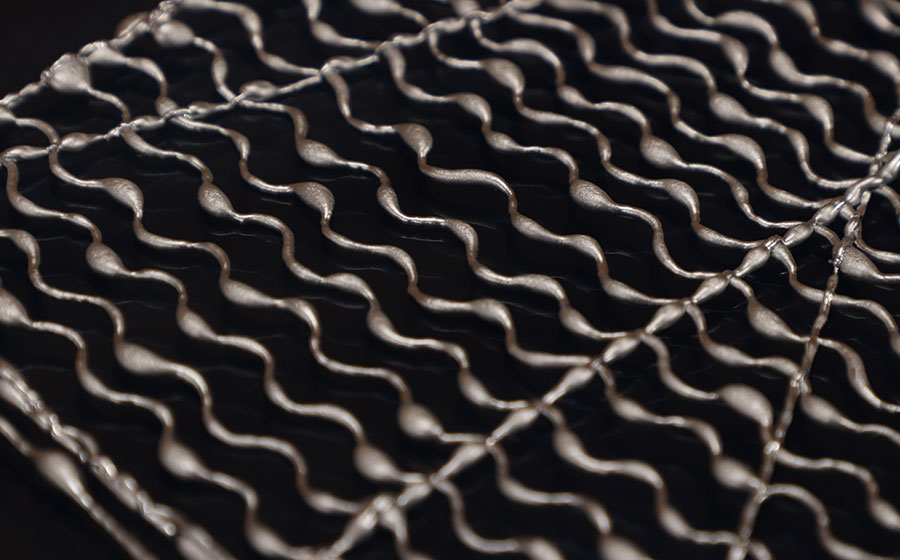

Development of a versatile tool for prototyping and batch creation of frames for lead/acid batteries.

Creating 3D printing technology from biomaterials and constructing a 3D bioprinter for the automated creation of bionic organs.