Development of hi-tech in Poland and Europe (we use the existing technological and personnel potential)

Production of carbon electronics resistant to harsh conditions

To transform into a company like EU TSMC for carbon electronics, not silicon electronics

High temperatures in the power industry

Low chemical resistance

Difficult conditions in space applications

Low temperature

Direct microscale gas-to-solid 3D printing technology

Glassy carbon (main material)

Lightweight

Durable / strong

Biocompatible

Good electrical and thermal conductor

Chemically and thermally resistant

Exhibits semiconductor properties

Closed and controlled working environment

We have full control over the chemical composition of the print and can dope the material

Precision of a focused laser beam

- Micrometer-scale objects

Printing on virtually any type of substrate

- such as SiC and hundreds of others

Combination of multiple materials

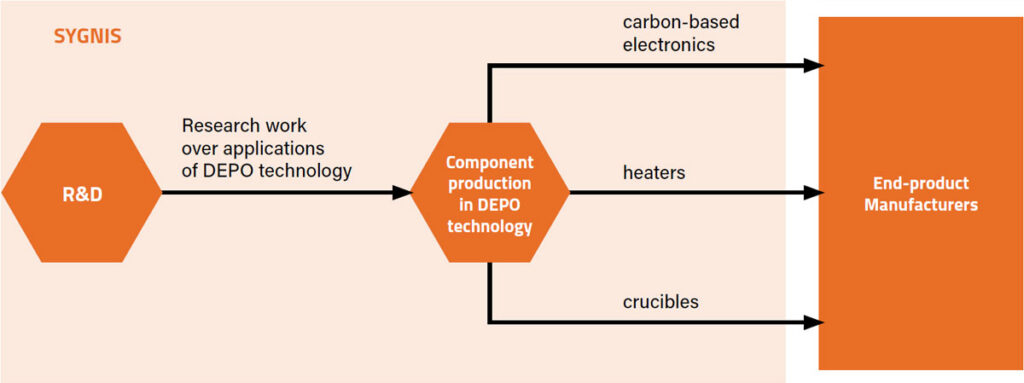

Business model

Planned position in the value chain: Supplier of advanced components

Kamil Kłosek

He joined Sygnis in 2021 as one of the engineers in the R&D team, and in 2022 became the leader of the DEPO project. Since then, he has led the DEPO project in technological development. He has many years of scientific experience in the field of epitaxial methods, confirmed by numerous publications and cooperation with international centers. A materials science specialist.